|

|

|

CV | DESIGN | ART | AUDIO | CONTACT |

|

A special double insulated glazing (30 cm thickness)

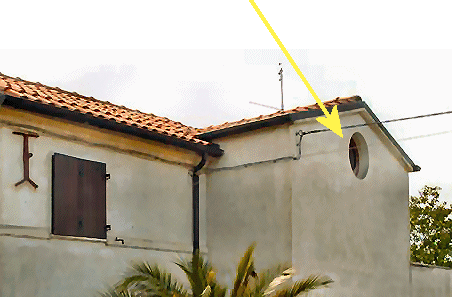

Targets: replacing an old porthole, controlling humidity due to indoor air condensation, increasing internal light

the original porthole was a single layer 3mm glass with a wooden structure which doen't guarantee a complete sealing, permitting air to condense into the internal side during cold seasons

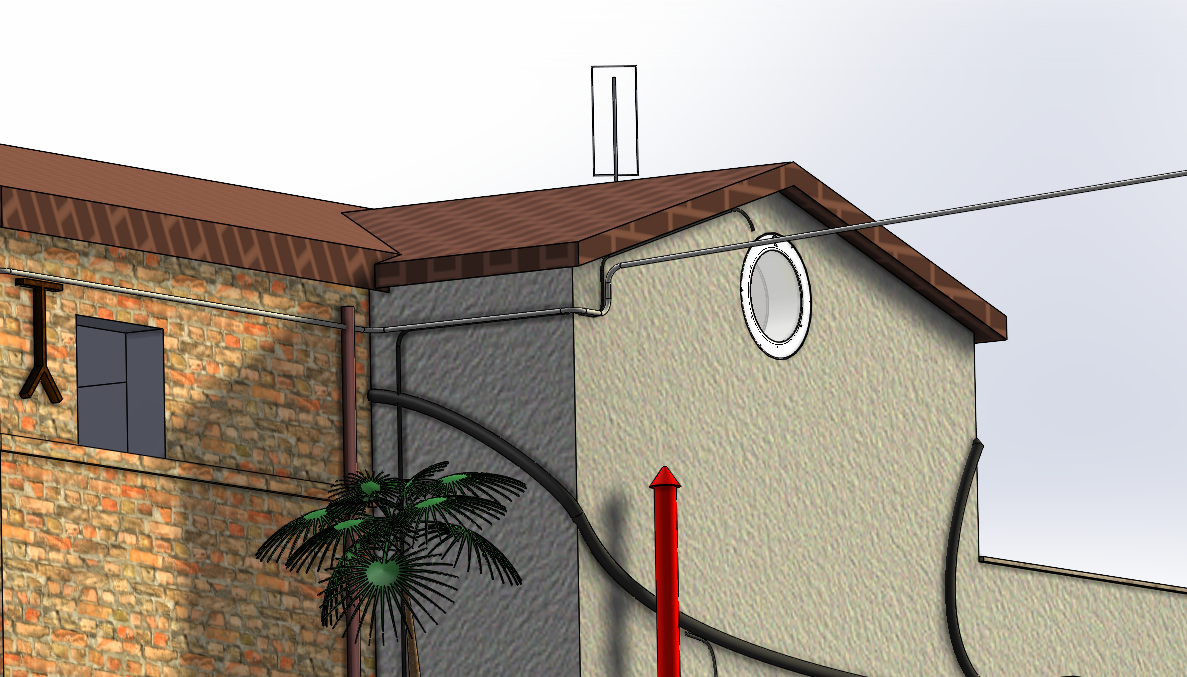

design of the environment and the new porthole

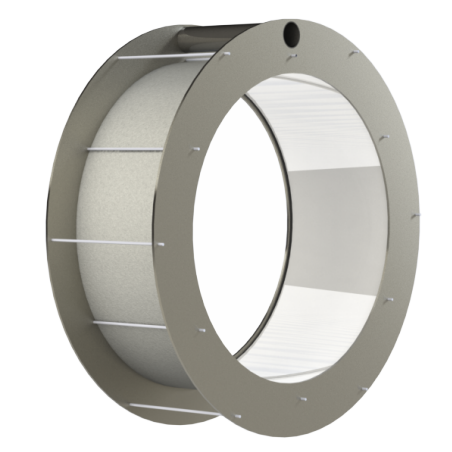

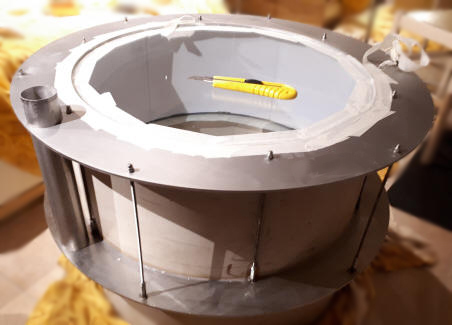

Used materials: 2 x laser cutting inox rings, PVC pipe Ø630mm, 2 x round glasses, layers of thermoplastic polymer, threaded rods, inox pipe, silica gel, led strip.

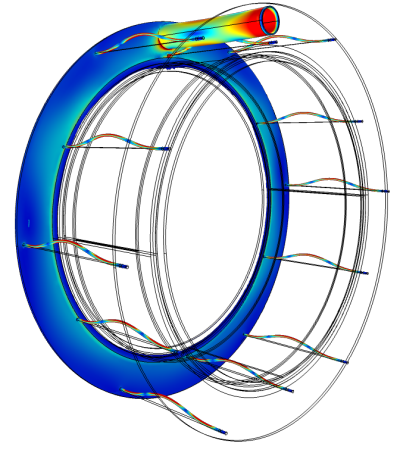

A structural mechanic simulation for the FEA 3D body is arranged to define the type and the minimum thickness for all solid materials, particularly for the two inox rings and the threaded rods which tighten the two inox rings maintaining in a constant pressure the whole structure. The total weight of the body is 45 kg, moreover one side of the body is exposed to external environment while the opposite side facing toward the inside of the house, thus in cold seasons temperature excursion between the two sides could reach more than 30 °C. It is necessary to pay attention to temperature variations and aging, fixing all parts with flexible joints to permit materials expansion.

Sequence of the construction phase

Assembling phase of the insulated glazing.

Installation phase

just painted indoor

and the final outside view

|